Can you drill into metal beams

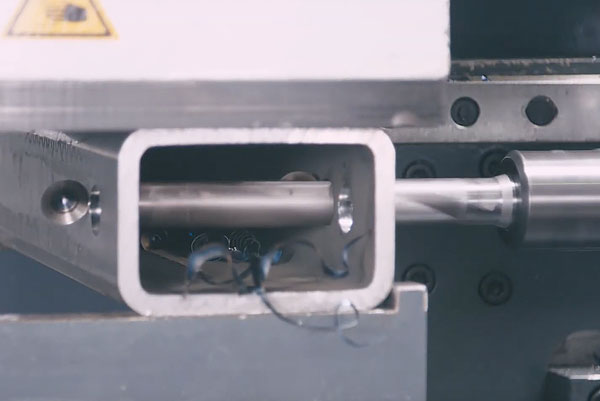

The Franklin HD145 (3) spindle CNC drill, with 44-inch width capacity. The HD-145 handles beams up to 750 lbs per foot. The hi-performance spindle design provides drilling capabilities up to 2,000 RPM. This rigid design provides extremely aggressive feed rates up to 300 surface feet per minute. The Franklin HD145 can be provided with several material handling packages from 300 lbs per foot, to 750 lbs per foot.

Voortman's 24 Hour Tech Support Center can resolve 90% of support issues. However, there are 50+ Voortman field personnel stationed all over North and South America, Europe and Africa.